Poultry Chiller Disinfection with Ozonated Water for Salmonella Control

Poultry Chiller Disinfection with Ozonated Water for Salmonella Control

Poultry chiller disinfection with ozonated water is increasingly used in poultry processing plants to reduce Salmonella risk and ensure continuous microbiological control throughout the cooling stage. The poultry chiller is one of the most critical points in the broiler slaughter process, as carcasses remain in contact with a shared water volume for an extended period, creating conditions for cross-contamination if water hygiene is not actively controlled.

Under these conditions, even low levels of initial contamination can lead to cross-contamination across the entire production flow. Conventional hygiene measures and low water temperature help slow bacterial growth, but they do not always provide sufficient control of pathogens such as Salmonella spp.. In practice, this means that passive control alone is often insufficient to achieve predictable and stable microbiological results.

As a result, increasing attention is being given to solutions that enable continuous disinfection of chilling water and active microbiological control throughout the entire cooling stage. One such solution is the use of ozonated water for filling poultry chilling tanks.

Why the Chilling Tank Is a Critical Control Point

In poultry processing, the chilling tank serves not only to rapidly reduce carcass temperature, but also represents one of the most sensitive stages in terms of microbiological safety. The microbiological condition of the water directly affects the safety of the final product.

Key factors that make the chilling tank a critical control point include:

Extended contact time

Broiler carcasses typically remain in the chilling tank for several minutes, providing sufficient time for contaminants to spread between carcasses.Shared water volume

The tank functions as a common medium for the entire production flow, increasing the risk of cross-contamination.Low water temperature

Temperatures around +1 °C effectively slow bacterial growth but do not eliminate pathogens, including Salmonella spp.Continuous water renewal and aeration

Water replenishment and aeration improve heat exchange but also contribute to uniform distribution of microorganisms throughout the water volume.

For these reasons, the chilling tank becomes not only a technological step, but a key microbiological control point where passive hygiene measures are often insufficient.

Use of Ozonated Water for Chilling Tank Disinfection

Given the limitations of traditional disinfection methods, solutions that provide continuous disinfection of process water are increasingly applied in poultry chilling systems. One of the most effective approaches is chilling tank disinfection using ozone through ozonated water.

Why Ozone

Ozone (O₃) is one of the strongest oxidizing agents used in the food industry. Its action against microorganisms is characterized by rapid reaction time and broad-spectrum effectiveness:

effective inactivation of bacteria, viruses, and other pathogens

destruction of microbial cell walls and genetic structures

faster action compared to most conventional disinfectants

An important advantage of ozone is that after reaction it naturally decomposes into oxygen, leaving no chemical residues in the water or on the product.

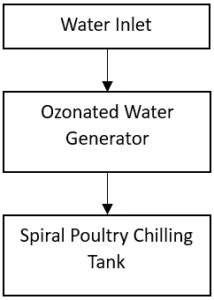

Why the Make-Up Water Is Ozonated

Applying ozonated water directly in the chilling tank make-up water line allows for a stable and predictable disinfection effect:

ensures continuous disinfection rather than a one-time treatment

operates independently of production load fluctuations

requires no structural modifications to the chilling tank

fully compatible with existing systems:

water circulation

aeration

low-temperature operation

In this way, ozonated water becomes an active hygiene component integrated into the existing technological process, transforming the chilling tank from a passive environment into a controlled microbiological zone.

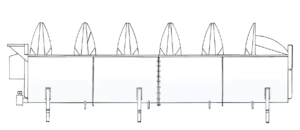

Typical Spiral Chilling Tank Configuration

Typical Spiral Chilling Tank Configuration

In poultry processing plants, spiral-type chilling tanks are commonly used to ensure uniform carcass movement, consistent residence time, and efficient heat transfer. This configuration is widely adopted in EU poultry plants due to its reliability and adaptability to different production capacities.

Typical operating principles of a spiral chilling tank include:

carcasses enter the tank sequentially and move along a spiral path

constant water level and temperature are maintained throughout the process

water is continuously renewed and mixed using circulation and aeration

Integration of ozonated water into such systems is simple and non-invasive. Ozonated water is supplied to the make-up water line before entering the chilling tank and is then evenly distributed throughout the water volume.

Process Parameters (Examples)

Ozonated water solutions can be adapted to different chilling tank configurations. Ozone-based disinfection of chilling tanks enables stable microbiological control regardless of operating conditions.

Typical industrial parameters include:

total water volume in the chilling tank: ~7-8 m³

water renewal rate: ~5-7 m³/h

water temperature: ~0 to +2 °C

carcass residence time: ~8-15 minutes

simultaneous load: ~700-1,000 broilers

average broiler weight: ~2.0-2.5 kg

water mixing: existing circulation and aeration

Ozone dosing is selected individually based on actual process parameters, ensuring continuous water disinfection without affecting line throughput or product quality.

Practical Application in EU Poultry Processing Plants

Ozonated water solutions are already applied in EU poultry processing facilities operating under strict food safety and hygiene requirements. Ozone integration into spiral chilling tanks is carried out under existing technological conditions, without the need for system redesign.

Key objectives of implementation include:

maintaining zero Salmonella detection at the chilling stage

reducing the risk of cross-contamination

ensuring stable and predictable hygiene performance

Worker Safety and System Operation

In ozonated water disinfection systems, ozone is used exclusively in the water phase. Small amounts of ozone may be released into ambient air; therefore, industrial installations are equipped with ozone concentration sensors.

If permissible limits are exceeded, the system automatically reduces or stops ozone generation. This approach ensures safe working conditions and reliable operation without continuous operator intervention.

Conclusions

Disinfection of poultry chilling tanks using ozonated water transforms this processing stage into an active microbiological control zone while maintaining existing technology and high worker safety standards. Unlike single-dose chemical disinfection, ozonated water provides continuous control throughout the entire cooling process.

This approach helps reduce Salmonella risk, limits cross-contamination, and enables more stable food safety outcomes in high-throughput poultry processing operations- without changes to line configuration or operating conditions.

Frequently Asked Questions (FAQ)

Can ozonated water be used for poultry chiller disinfection?

Yes. Ozonated water can be used for continuous disinfection of poultry chiller tanks, providing stable microbiological control throughout the cooling process. Unlike single-dose chemical treatments, ozone acts continuously in the water phase.

Does ozone disinfection require changes to existing chiller technology?

No. Ozonated water systems are integrated into the make-up water line of the chiller and do not require redesign of the chiller, changes to carcass residence time, or modifications to line capacity.

Is ozonated water safe for employees?

Yes. When designed and operated according to industrial safety standards, ozonated water systems are safe for personnel. Ozone is applied exclusively in the water phase for disinfection purposes.

Can ozone transfer from water into the processing hall air?

Small amounts of ozone may off-gas from water, especially during circulation and aeration. For this reason, industrial installations are equipped with continuous air monitoring using ozone sensors. If preset safety thresholds are exceeded, ozone generation is automatically reduced or shut down.

Does ozone disinfection affect carcass quality or appearance?

No. Ozone decomposes naturally into oxygen and leaves no chemical residues. It does not affect the appearance, odor, or quality parameters of poultry carcasses.

Is this solution suitable for high-capacity poultry processing plants?

Yes. Ozonated water disinfection is successfully applied in high-throughput poultry plants operating under continuous production режимes, where process stability and predictable hygiene performance are critical.

Does ozone help reduce Salmonella risk in chiller tanks?

Yes. Practical applications show that continuous chiller water disinfection using ozonated water significantly reduces Salmonella risk and limits the potential for cross-contamination during the cooling stage.

Learn more about ozone solutions

If you are evaluating how to improve poultry chiller hygiene and reduce Salmonella risk without modifying existing technology, we invite you to explore our solutions:

Ozone solutions for industry – Ozone Solutions

Industrial ozone equipment – Products

High-concentration ozonated water generator – High-Concentration Ozone Water Machine

For technical consultations, feasibility assessment, or discussion of your specific process parameters, please contact us directly:

Contact us – Contact Us

E-mail: info@guolin.eu

Each project is assessed individually, taking into account real operating conditions, hygiene requirements, and production capacity.

The approach described here reflects only one element of a broader ozone technology application framework.

How Guolin Technology Group defines the role, limitations, and system-level integration of ozone is explained in

Guolin ozone technology.